Ultimate Guide To Conduit Wiring Practices

Conduit wiring offers a smart solution for safe and organized electrical installations. By encasing wires in protective tubing, conduit wiring minimizes the risk of damage and ensures a sleek finish. This method is the go-to choice for residential and industrial projects alike. With its durability and versatility, conduit wiring provides a reliable electrical system that meets modern standards. Discover the benefits and best practices of conduit wiring in this comprehensive guide.

Exploring Conduit Wiring: What You Need to Know

Welcome, young electricians in the making! Today, we’re diving into the fascinating world of conduit wiring. Have you ever wondered how electricity travels through your home safely and efficiently? Well, conduit wiring plays a crucial role in this process. Let’s embark on a journey to understand the ins and outs of conduit wiring, from its basics to its significance in modern electrical systems.

The Basics of Conduit Wiring

First things first, what exactly is conduit wiring? Imagine a protective tunnel that guides electricity from one point to another within a building – that’s conduit wiring for you! Instead of leaving wires exposed, conduit wiring keeps them secure and shielded from damage. It’s like a secret passageway for electricity to flow without any interruptions.

Conduits can be made of metal, such as steel or aluminum, or non-metallic materials like PVC. Each type of conduit has its advantages and specific uses depending on the installation requirements. The wires placed inside the conduit are insulated to prevent electrical shocks and ensure a smooth flow of current.

Types of Conduits

There are different types of conduits used in electrical installations. Let’s explore a few common ones:

1. Rigid Metal Conduit (RMC)

RMC is a heavy-duty conduit made of galvanized steel. It provides excellent protection against physical damage and is commonly used in industrial settings or areas where the wiring needs extra durability.

2. Electrical Metallic Tubing (EMT)

EMT is a lightweight and easy-to-install conduit made of thin steel. It is often used in residential settings where flexibility and cost-effectiveness are key considerations.

3. PVC Conduit

PVC conduits are non-metallic and typically used in environments where corrosion or chemical resistance is essential. They are also commonly used for outdoor electrical installations due to their weatherproof properties.

The Importance of Conduit Wiring

Now, you might be wondering, why is conduit wiring so important? Well, let’s unravel the reasons behind the significance of this essential component in electrical systems:

1. Safety First

Conduit wiring enhances safety by protecting wires from physical damage, moisture, and other environmental factors. This reduces the risk of electrical hazards such as short circuits or fires, making your home or workplace a safer place to be.

2. Durability and Longevity

By providing a secure housing for electrical wires, conduit wiring ensures the longevity of the electrical system. Wires inside conduits are less prone to wear and tear, extending the lifespan of the entire installation.

3. Easy Maintenance

Conduit wiring simplifies maintenance and troubleshooting processes. Since the wires are neatly organized within the conduit, identifying and fixing issues becomes more straightforward. Electricians can access and repair the wiring without disrupting the entire system.

Installing Conduit Wiring

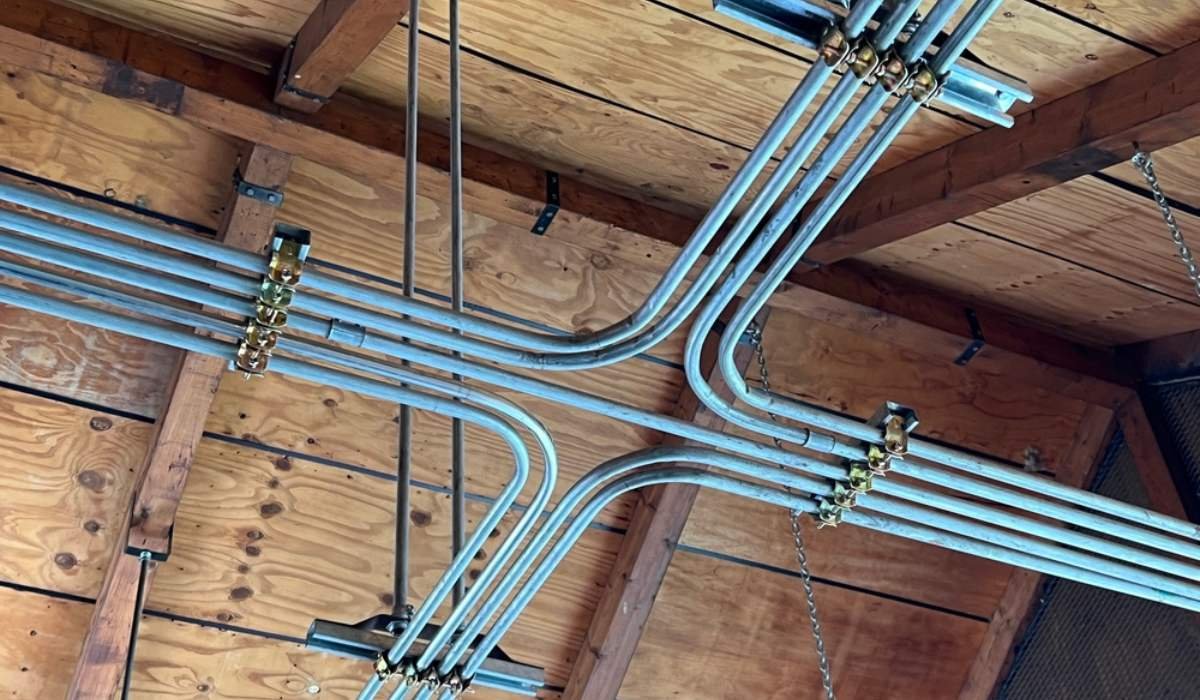

Now, let’s talk about how conduit wiring is installed. It’s like putting together pieces of a puzzle – each wire has a designated path to follow within the conduit. Here’s a simplified overview of the installation process:

1. Planning and Preparation

Before starting the installation, electricians plan the conduit layout based on the building’s design and electrical requirements. They gather the necessary tools and materials, ensuring everything is ready for the task ahead.

2. Routing the Wires

Electricians carefully route the wires through the conduit, making sure to avoid sharp bends that could damage the wires. Proper organization and securing of the wires are crucial for a successful installation.

3. Connecting the Conduits

Once the wires are in place, electricians connect the conduits to electrical boxes, outlets, or switches. This step requires precision and attention to detail to ensure a secure and reliable connection.

4. Testing and Inspection

After the installation is complete, electricians conduct thorough testing to verify the integrity of the wiring. Inspections may also be carried out to ensure compliance with electrical codes and regulations.

Advancements in Conduit Wiring Technology

As technology continues to evolve, so does conduit wiring. Modern advancements have led to innovative solutions that enhance the efficiency and effectiveness of electrical systems. Let’s explore some of the exciting developments in conduit wiring technology:

1. Smart Conduits

Smart conduits are equipped with sensors and monitoring devices that can detect faults or abnormalities in the wiring. These advanced systems provide real-time data and alerts, allowing for proactive maintenance and troubleshooting.

2. Energy-Efficient Conduits

Newly designed conduits focus on energy efficiency, reducing power loss and optimizing electrical performance. By incorporating eco-friendly materials and design features, these conduits contribute to a more sustainable and cost-effective electrical infrastructure.

3. Wireless Conduit Systems

Wireless conduit systems eliminate the need for physical wires, enabling remote and flexible control of electrical devices. This wireless technology simplifies installations and offers greater convenience in managing electrical systems.

The Future of Conduit Wiring

Looking ahead, the future of conduit wiring is filled with endless possibilities. From enhanced safety features to greater connectivity and automation, conduit wiring will continue to play a vital role in shaping the electrical landscapes of tomorrow. So, as you embark on your journey in the world of electrical work, remember the important role that conduit wiring plays in keeping our homes and workplaces powered safely and efficiently.

And there you have it, young electricians! Conduit wiring may seem like a simple concept, but its impact on electrical systems is truly remarkable. Keep exploring, learning, and tinkering with wires – who knows, you might just illuminate the future with your electrical wizardry!

#1 DIY Electric Mistake – Can you use Romex Wire in Conduit?

Frequently Asked Questions

What is conduit wiring?

Conduit wiring is a method used to protect electrical wires by running them through metal or PVC pipes called conduits. This provides a secure and enclosed pathway for the wires, ensuring safety and preventing damage.

Why is conduit wiring preferred in some installations?

Conduit wiring is preferred in certain installations because it offers better protection against physical damage, moisture, and corrosive environments compared to exposed wiring. It also helps in reducing the risk of electrical hazards and makes maintenance easier.

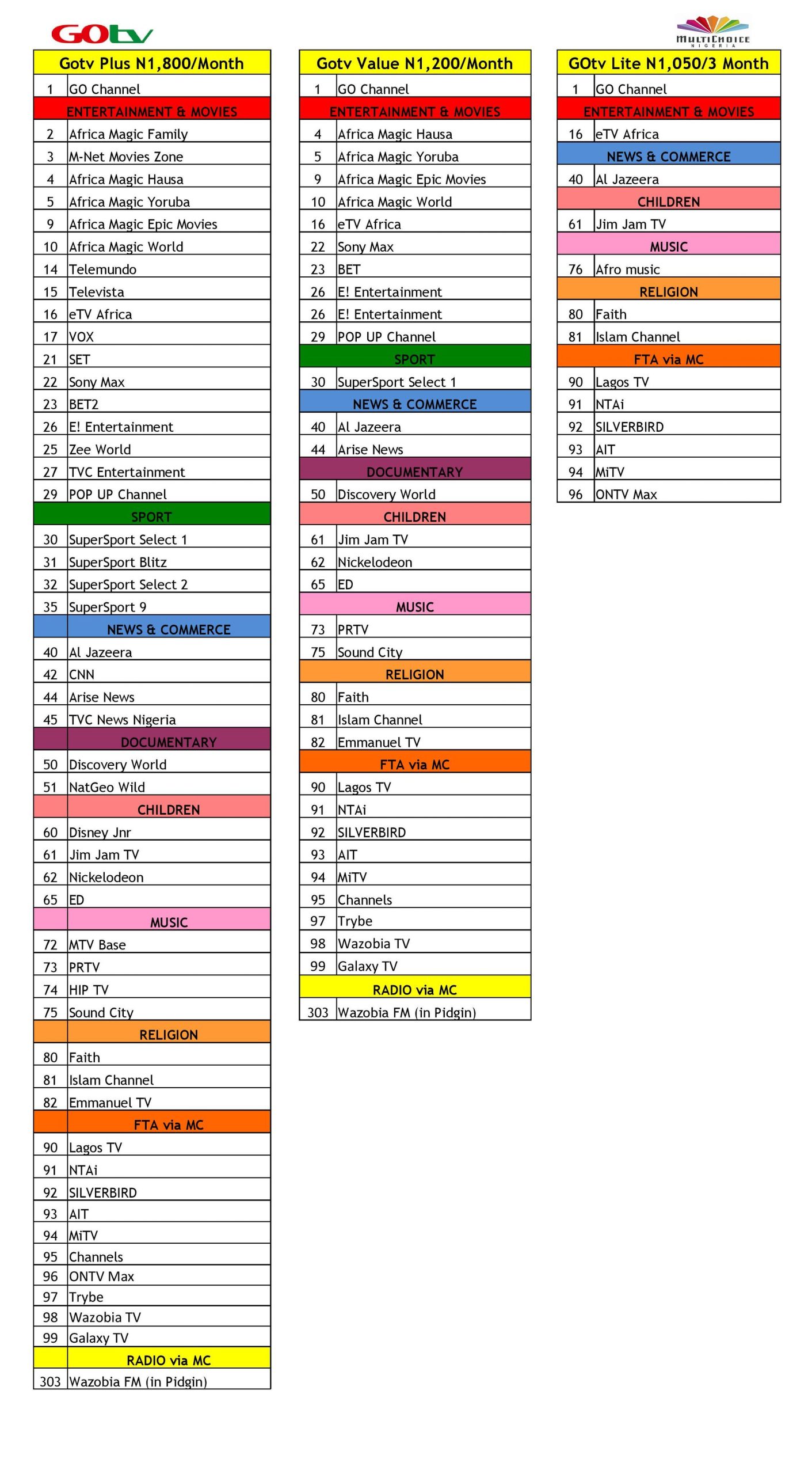

What are the different types of conduits used in conduit wiring?

Common types of conduits used in conduit wiring include rigid metal conduits, flexible metal conduits, PVC conduits, and electrical metallic tubing (EMT). Each type has specific applications based on the wiring environment and requirements.

How is conduit wiring installed in a building?

To install conduit wiring in a building, the conduits are first fixed securely to the walls or ceilings. The electrical wires are then pulled through the conduits, ensuring proper connections and organization. Finally, the conduits are sealed and grounded to complete the installation.

Final Thoughts

Conduit wiring offers a safe and durable solution for electrical installations. It provides protection against physical damage and reduces the risk of fires caused by electrical faults. By enclosing wires in metal or plastic conduits, conduit wiring ensures proper insulation and grounding. Overall, conduit wiring is a reliable method that enhances the safety and longevity of electrical systems.